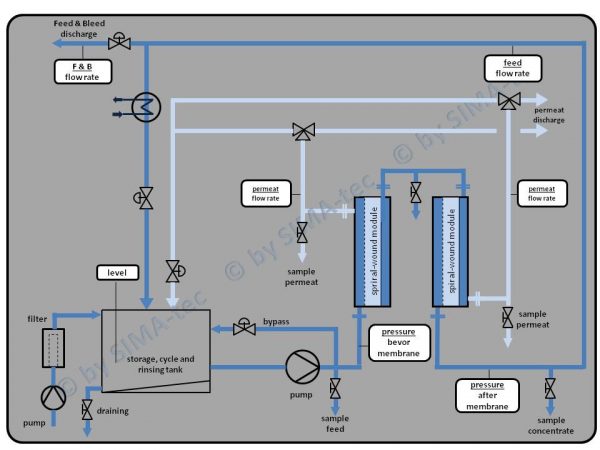

Hand-controlled membrane test unit for pilot tests (PSta15-2)

The hand-controlled membrane test unit is a universal membrane test and small-scale production unit for carrying out test and pilot tests in the field of nanofiltration and low-pressure reverse osmosis.

In the version described here, the PSta15-2 has two serially connected stainless steel pressure tubes (here 2.5”) for accommodation various commercially available NF and/or UO technical winding modules. Its flexible design allows the adaption of various other stainless steel pressure tubes. The universal equipment of the system and the flexible use of various 2.5” winding modules enable experiments to be carried out over a wide range of industrial applications.

The unit is designed as a manually controlled system. However, it can also be designed as a PLC-controlled and/or fully automated system. The process parameters are variable and can be individually adapted at any time. All measurement and control data can optionally be recorded, standardised and visualised via an external data acquisition system (SIMA-tec measurement box). The test data is stored in a format that can be read by excel.

Field of use:

- Comparison of nanofiltration and low-pressure osmosis at the same time

- Experiments comparing different membrane materials and geometries

- Investigation of the tendency to blockage

- Investigation of cleaning strategies / cleaning techniques

- Experiments to optimise process parameters of industrial applications

Further technical information can be found in the data sheet.

Have we aroused your interest? Or is the system for your application not yet included? No problem! Please contact us. We will be happy to help you.