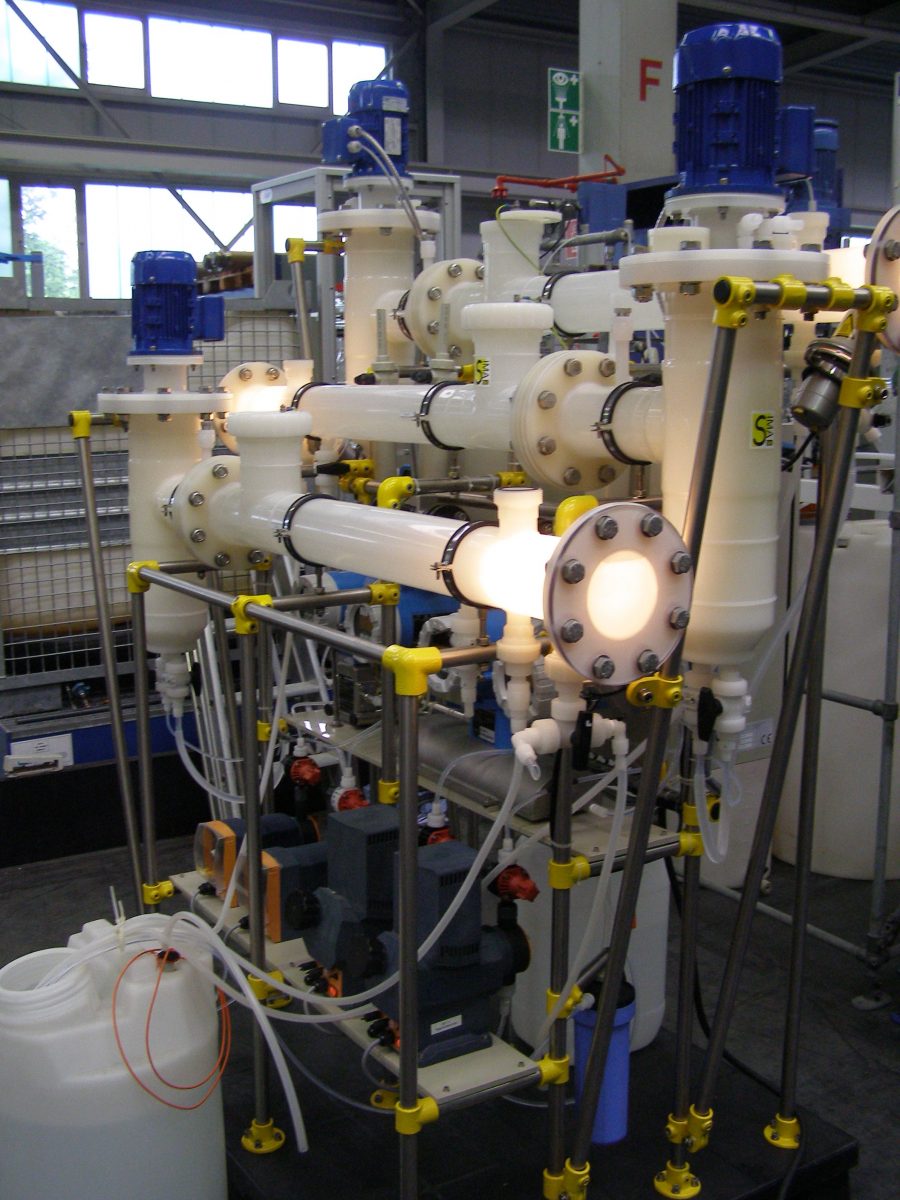

Extraction (Mixer-Settler) DN100 (MS)

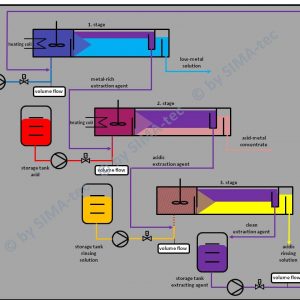

The extraction test unit is designed as a Mixer-Settler system in DN100. It is a universally applicable three-stage unit for liquid/liquid extraction. The unit was designed and built for extraction experiments of valuable metals from spent or saturated pickling acid or rinsing waters from the electroplating industry. Therefore, all stages are designed in PVDF, so that a high chemical resistance is ensured and in particular fluoride-containing solutions can be processed. The extraction of the metals takes place in the first stage, the two subsequent stages serve for the preparation of the extraction agent.

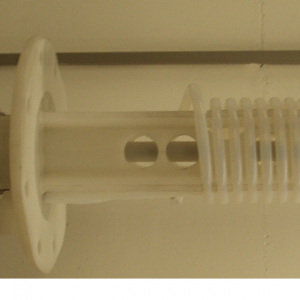

Mixer and Settler areas of each stage are separated by overflow weirs. At the end of each Settler area is an overflow weir with dip tube to separate the “light” phase and a riser to separate the ”heavy” phase. To evaluate the phase separation, the Setters have halogen lamps. The speed-controlled stirrers installed in the Mixer area are adjusted in their direction of rotation in such a way that they have a suction effect. To set the desired reaction temperature, the Mixer areas of the first two stages have a heating coil with thermostat.

Field of use:

- Experiments for the liquid/liquid extraction of valuable metals from metal-bearing solutions in the first stage

- Experiments to treat extractants in the second and third stage

- Experiments with highly concentrated solutions

- Optimization of process parameters

Further technical information is given in the Data Sheet.

Are you interested? Or could you not find your wanted test unit yet? No problem! Contact us! We would be happy to give you advice!